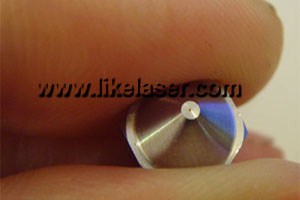

chopper_machining_China_荣皋供

Shanghai Ronggao laser, in laser drilling, cutting, marking, welding and other fields for more than 10 years, the company's internal engineers, skilled, dedicated and responsible, has been with a number of large state-owned enterprises and research institutes, universities. The feasibility and innovation of the joint experimental laser in the new materials have greatly broken through the previous processing efficiency and technical bottleneck. We can achieve micron hole. Some materials can even achieve nano-level micropore processing. Processing time is short, high efficiency.

0.001mm、0.01mm、0.11mm,0.002、0.021、0.2and so on.

Laser micro hole processing equipment parameters:

The machining accuracy: less than 0.002mm.

Micro machined surface roughness: Ra ≤ 0.6 um.

Diameter range of microporous: 0.01~ 0.001mm.

Roundness of microporous processing < 0.002mm.

Single hole processing time is less than 1 second (see material and drawings specifically).

Micropore size: 0.001mm, 0.01mm, 0.11mm, 0.002,0.021,0.2 and so on